Ion beam figuring (IBF)

An eraser tool for surface errors

In ion beam figuring the goal is to create, by locally sputtering atoms, a surface with a specified profile. It is a technique that can be used for precise figuring and finishing of optical elements, such as spheres, aspheres and free forms on lenses and mirrors. IBF is typically the final processing step after mechanical polishing.

Ion beam figuring: how does it work

In ion beam figuring the desired contours are achieved by rastering an ion beam across the workpiece at varying velocities. Through the control of the dwell time at different locations the removal of material can occur with great precision.

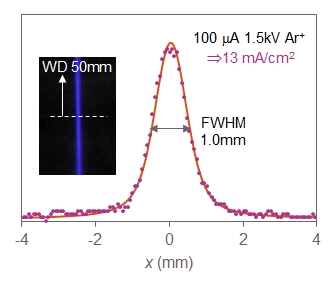

Successful ion beam figuring corrects surface errors without generating subsurface damage or roughening of the surface, and does not introduce impurities to the surface. For effective IBF the ion beam should be very stable and deliver a current density of at least several mA/cm².

Ion Beam Figuring & Polygon Physics

Beam parameter flexibility

Ideally surface errors are removed without damaging the surrounding and underlying material. Important factors that influence this are the beam size and shape, and its energy. Our ECR technology and ion optics system offer the user a highly useful flexibility in these parameters to control the surface damage.

Contamination-free

Obviously it is also preferred that the IBF process does not introduce any contamination to the surface. Contamination can be introduced when sources are configured with grids and/or beam limiting apertures. Grids and apertures can be used to extract and shape the ion beam and are placed in the beam path. When the beam hits these grids or beam-limiting apertures it can sputter the grid or aperture edge. This sputtered material can subsequently contaminate the treated surface. Our sources can operate with aperture electrodes for which the beam path remains unobstructed, and thus contamination-free.

Beam stability

A third factor in IBF is beam stability and reliability. This can be tricky when it comes to sources operating with hot filaments. The technology we use in our sources does not rely on hot filaments, but on ECR plasmas. ECR plasmas are inherently stable and reliable, and thus in that sense suitable for ion beam figuring.

TES | Ion mill for IBF

In addition to the arguments above, our Ion mill is well adapted to ion beam figuring of smaller surface errors for the following reasons:

- can deliver around 10 mA/cm² with a maximum total current of a few hundred µA

- can be mounted anywhere inside a vacuum system using only flexible cables to the flange

- is compact and easy to use (no microwave tuning etc)