TES | Ion mill

Polygon Physics’ TES Ion mill delivers focused ion beams for ion milling and ion beam figuring purposes with energies up to 30keV.

Source concept

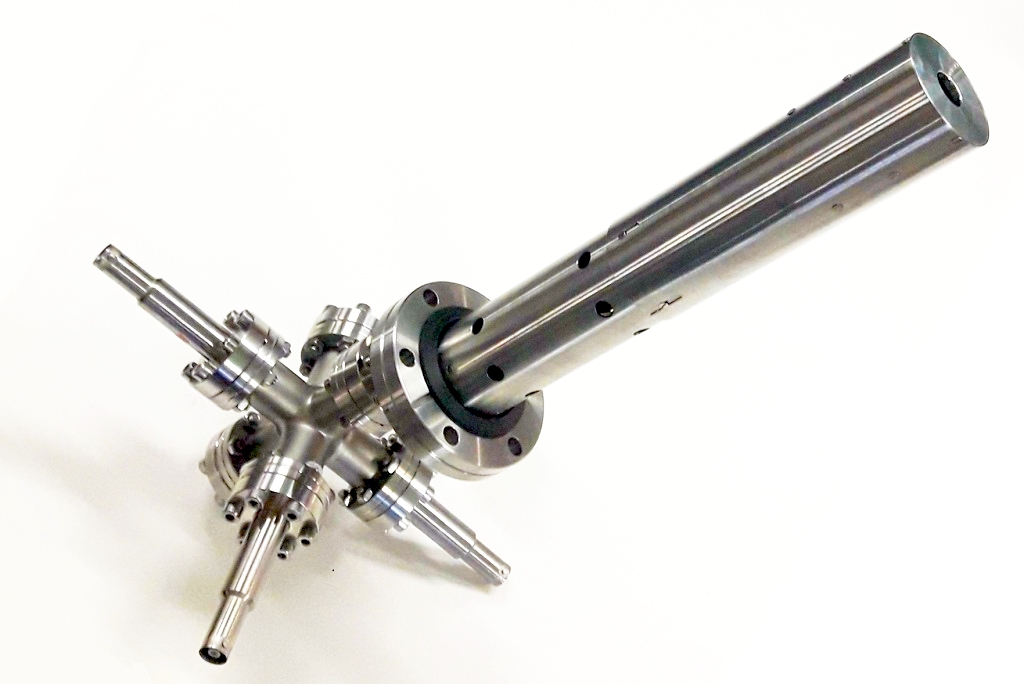

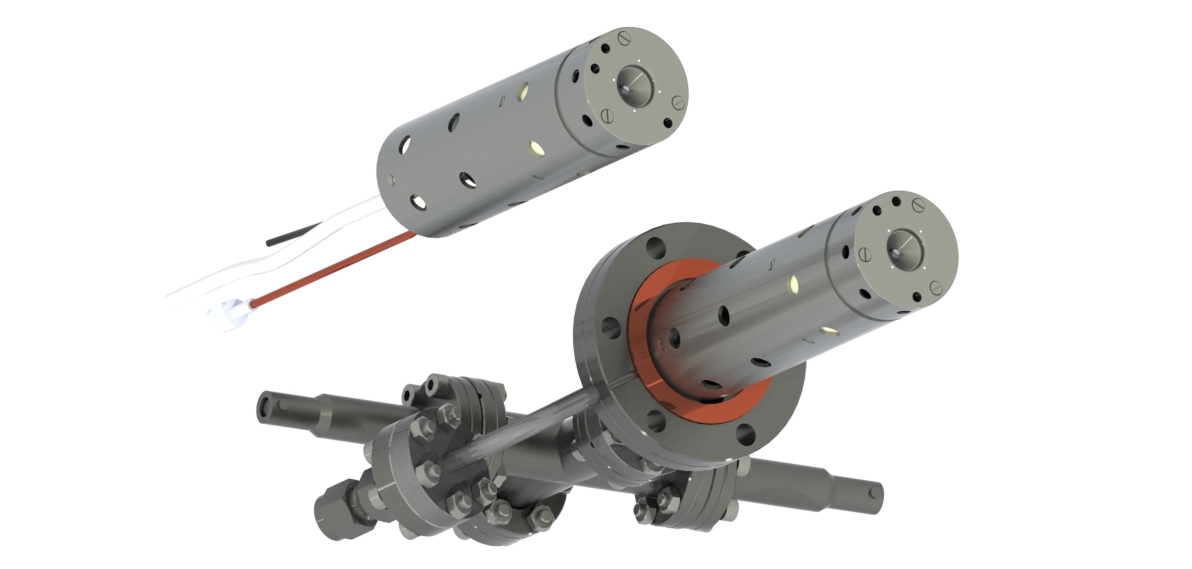

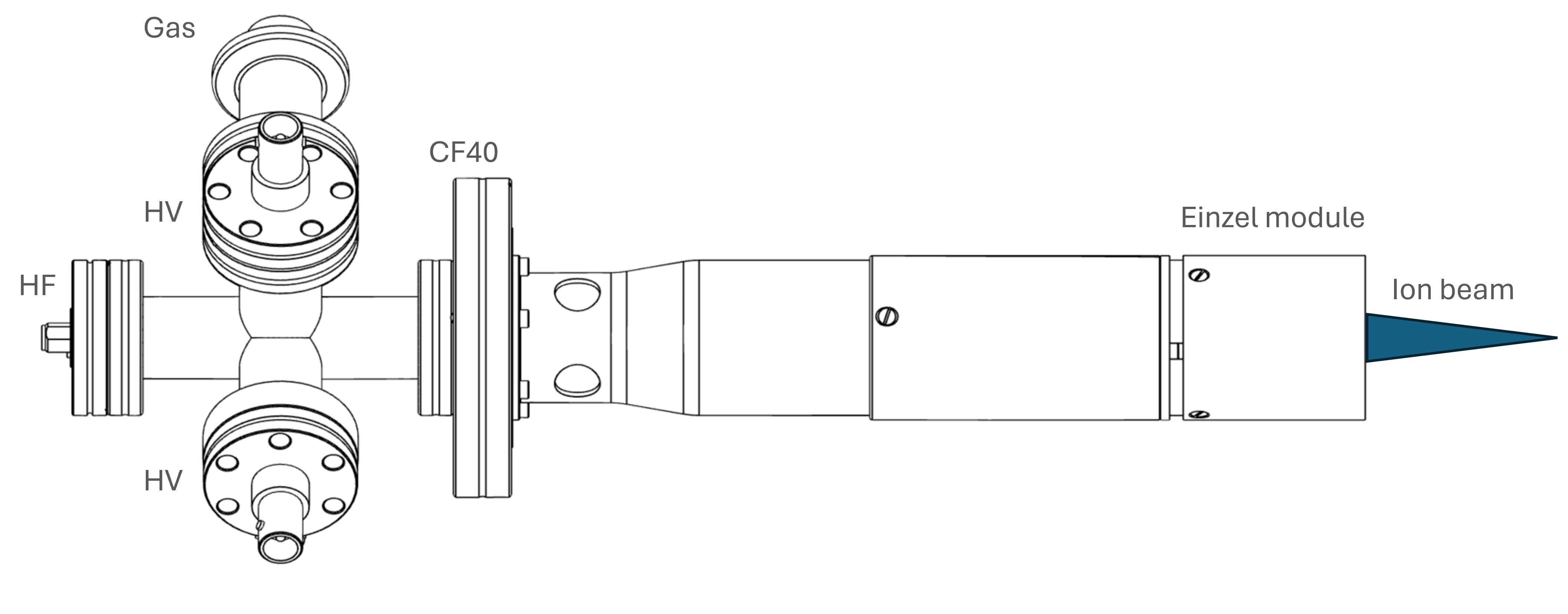

The core element of TES is a patented microwave discharge system (ECR-plasma) that operates at ultralow power and is as small as a thumb. You can find more about the technology here. The extraction system connected to the cavity determines the nature of the particles that leave the source. TES Ion mill is configured with an Einzel lens to produce focused beams on the sample with high current density. The ion current can be varied over a wide range by tuning the gas flow rate, the applied microwave power, and the strength of the extraction field, independently from the beam energy. Through closed loop regulation of the UHF power the beam current can be made extremely stable.

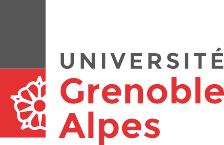

Source coupling to the flange: rigid or flexible

Main features

- Plug & play (no microwave tuning)

- Filamentless

- No cooling

- Noble and reactive gases

- Variable spotsize (from sub-mm to cms)

- UHV-compatible

- Automated source operation

- Closed loop current regulation

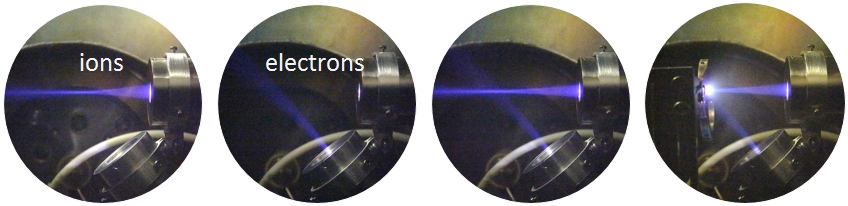

Neutralization

Ion beam sputtering of insulating materials can cause undesirable charging effects. An electron source can compensate these charges. Polygon Physics offers an ECR-plasma based neutralizer which has the same core element TES sources have. This type of neutralizer is inherently stable, and has a long lifetime due to the absence of any consumables such as filaments. Contact us if this could be of interest to you.

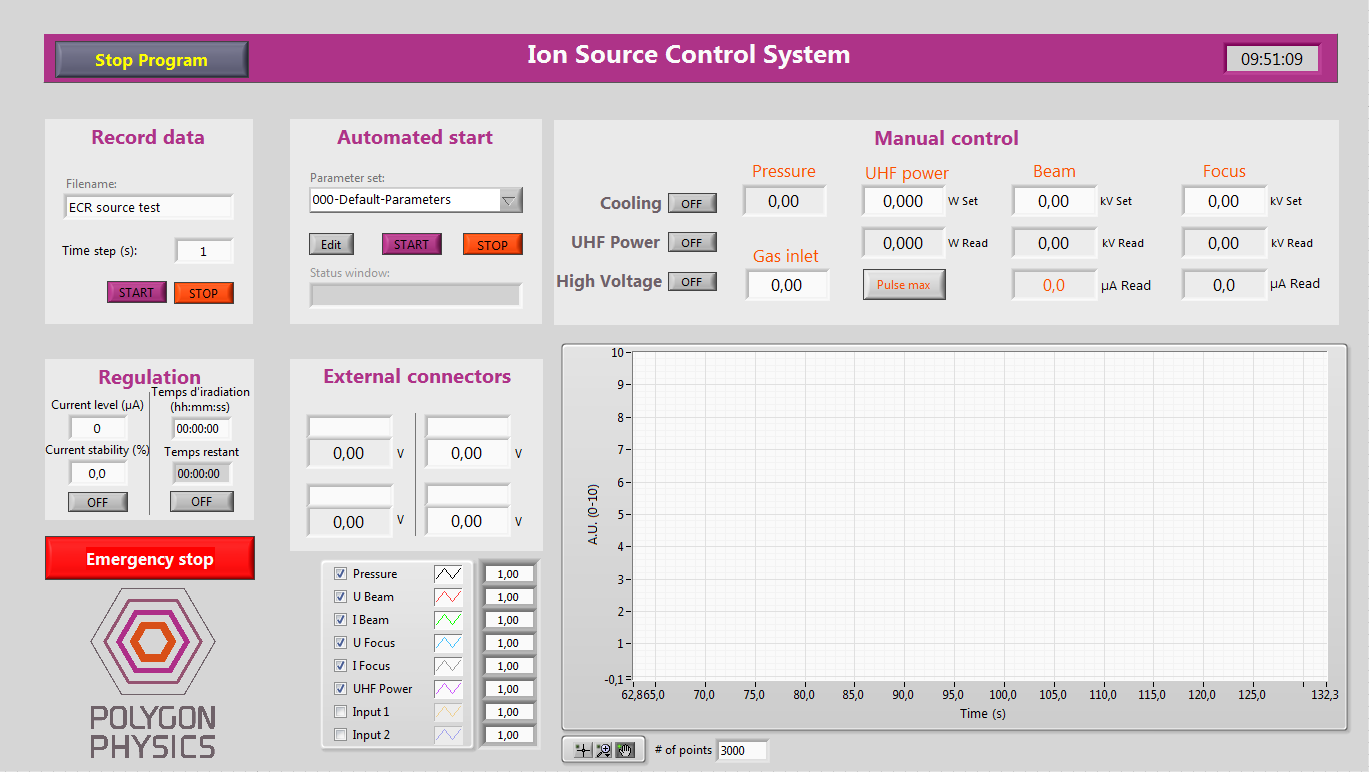

Software

The source comes with a user-friendly control & monitoring interface, that allows you to control the beam, record data, and run stored recipes. The GUI user Interface is available with an API that allows you to easily integrate the source into your system environment.

Technical data

TES Ion mill comes equipped with an Einzel module, to focus the ion beam at the sample. Due to this module the diameter of the beam that hits the surface can be squeezed to sub mm dimensions. This in combination with a high beam current, and beam energy up to 30keV, ensures high local milling rates. For more gentle milling the beam energy can be reduced. The UHF power required for operation is at most 5W, for a maximum beam current of more than 500µA. The gas flow (typically a few sccm) can be regulated with either a mass-flow controller or a microleak valve. TES Ion mill can be either mounted onto a CF 40, CF 63 or CF 100 flange for beam energies up to 5keV, 15keV or 30keV respectively (according to your energy range), or remotely through flexible cables to allow for source movement under vacuum. Due to the absence of grids and filaments, the beam is stable and reliable, and maintenance is low.

The source module is delivered with 19¨ rack-mount electronics, HF and HV cables, power cord and software. Not included are the source gas and PC. TES can be customized to match your specific application. Contact us for the various possibilities available to suit your particular needs.

Example of a TES-40 source set-up.