Multi Beam Sputter Deposition Systems

Ion beam deposition ‘the easy way’

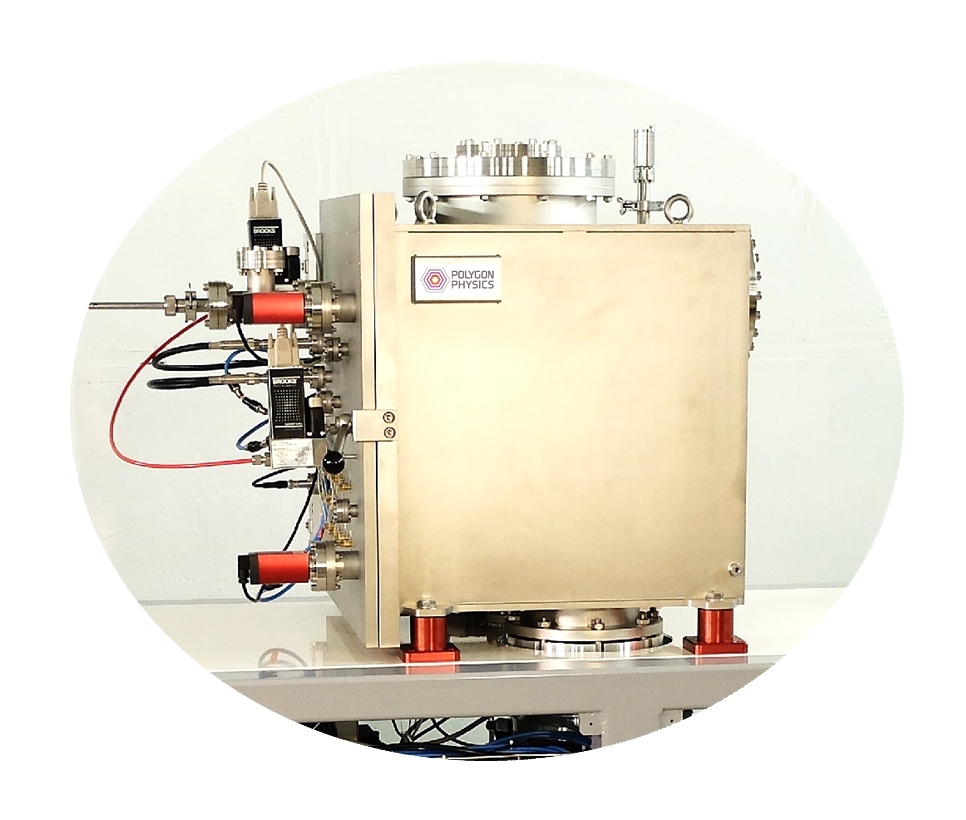

Systems for ion beam deposition are generally considered to be bulky and complicated. With our multi beam deposition systems we try to break with this idea. We believe that due to the completely different concept of our systems, ion beam deposition can now be done ‘the easy way’.

Tunable deposition parameters

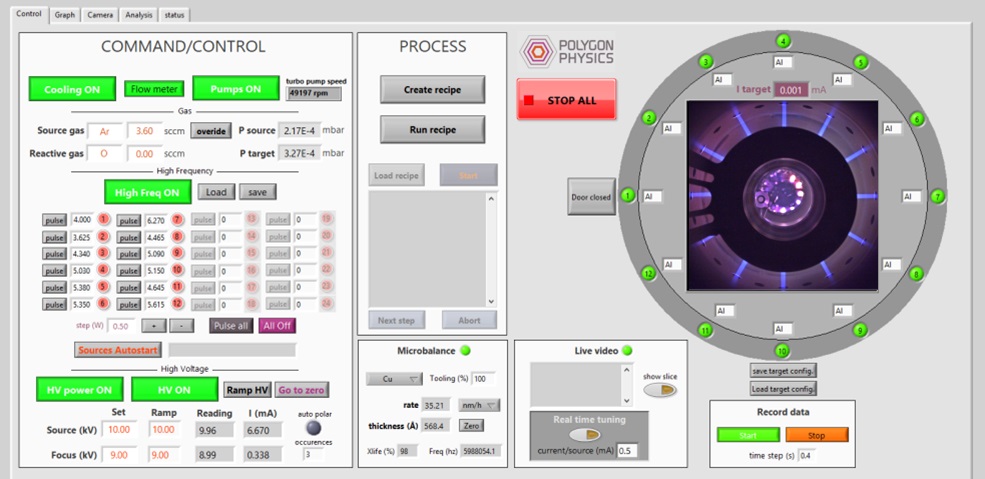

Easy system operation

Low system maintenance

Our method is “sample-friendly”, just as conventional ion beam sputter deposition methods: substrates can be of sensitive nature, as they are not attacked by plasma (plasma is confined to the source cavities), sample biasing is not required, and sample heating is minimal.

The film quality that our systems deliver is typical for ion beam sputter deposition. Films are dense & smooth, often nanocrystalline in nature, and contain no noble gas (from the sources). The non-standard geometry of our system can yield semi-conformal depositions.

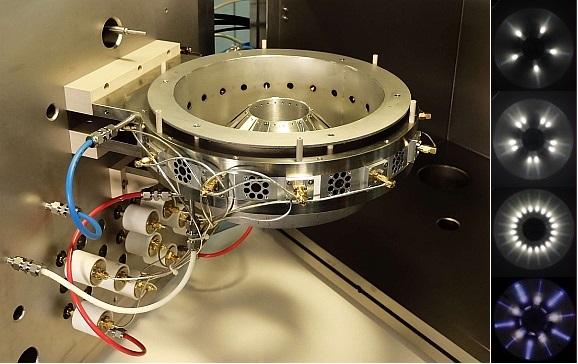

Multi-component thin films in many varieties

The source technology employed in our deposition systems offers enormous possibilities for multi-component thin films. This is, first of all, because our ECR ion sources have a large operating window both beam current and energy. Secondly, each source is controlled individually through individual RF power supplies. And finally, the sources are easy to turn on and off individually. This enables the uniform deposition of multi-component materials, but also the controlled deposition of nonuniform multi-component materials. Nonuniform compositions across a substrate can be of interest for combinatorial thin film synthesis, aiming at rapid material discovery. A nonuniform composition in vertical sense can be useful for better adhesion of a film on a substrate, but for example also to create a continuously varying refractive index.

Deposition of alloys & compounds

Functionally graded thin films

Multilayer deposition

System specifications (MBS-24)

- 50x50x50cm vacuum chamber

- Ø32cm source-ring

- up to 24 ion sources (indiv. RF power supplies)

- 0-500 µA per ion source

- 5-10kV ion beam energy

- Oil cooling (source ring & targets)

- Roots pump 15 m3/h, turbo pump 700 l/s

- Source gas inlet: e.g. Ar, Xe

- Recipe depositions

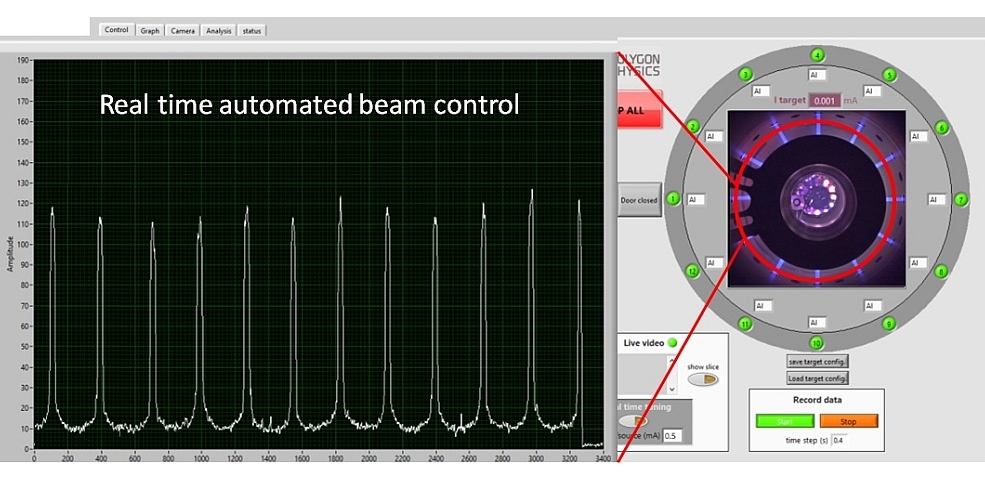

- Real time automated beam tuning

- Customizable sample (top) loading

- ±2% uniformity for 70nm/h on Ø10cm (static)

- Uniform films up to 4 components

- Reactive gas inlet: e.g. O2, N2

- Film thickness monitor